Dockweiler Japan Co., Ltd.

Hikawazaka Bldg. 2F

6-8-9 Akasaka

Minato-ku, Tokyo

107-0052

Japan

For more than 60 years our family-run company has stood for top quality, excellent service, innovative solutions and above all: Trust.

Over 750 exceptionally well-trained and motivated employees, whose expertise and reliability form the basis for the success of the Dockweiler Group, safeguard the interests of our customers.

Dockweiler AG, now led by third-party managers, belongs to the Dockweiler Group, a second-generation family holding company whose company founder, Klaus-Dieter Fiebig, recognized the relevance of high purity surfaces in the production of high-performance memory chips and processors back in the 1970s, laying the foundation for the sustained technical success of present day Dockweiler AG.

With our innovative products and customer solutions we have contributed to and influenced industrial development trends.

Behind the company, we as a family stand for innovation with tradition, commitment and fairness with the knowledge that the satisfaction of our customers, suppliers and employees is the core value of our company.

We three daughters, Susanna Fiebig, Sonja Wilke and Julia Neth, will continue to take the company into the future, using our father's principles and values as a guide.

At the beginning of the 1970s Klaus-Dieter Fiebig launched the business with high purity stainless steel tubes and fittings. Very early on he recognized the importance of high purity surface qualities for the beginning computer age. With a willingness to take risks and a pioneering spirit, the course for today's company development was set early on.

Establishment of our new Advanced Lithography business unit with the target of staying one step ahead of the ever-increasing demands of the semiconductor market.

Expansion of electropolishing capacities at our subsidiary Calamo AB in Sweden.

Expansion of the administration and production buildings as well as photovoltaic installations at Dockweiler AG.

Dockweiler establishes subsidiary in the USA and India.

Takeover and integration of Dockweiler Industrial Automation GmbH.

Dockweiler opens a subsidiary in China.

Company founder Klaus-Dieter Fiebig and his daughter Sonja Wilke jointly manage the holding company.

For the third time running, Dockweiler apprentices receive "Trainee of the Year" award from the Schwerin Chamber of Industry and Commerce.

Dockweiler is Europe’s first and only ASME BPE certified manufacturer of tubes and fittings. Dockweiler is the only manufacturer in the world to offer not only fittings and tubes, but also other materials according to ASME BPE, Part MM, e.g. AL-6XN and 1.4435.

Dockweiler Japan opens in Japan.

Dockweiler Middle-East opens in Israel.

Commissioning of in-house cleanroom, class 4 + 6.

Dockweiler Asia opens in Thailand. This is the delivery headquarters for Asia concentrating sales there. At the same time, a production facility with an electropolishing plant for pharmaceutical products is built.

Klaus-Dieter Fiebig steps down as Chairman, reorganizes to external management and transfers his majority share in the company to his three daughters. This ensures transition of the family business to the next generation. He remains however Managing Director of Dockweiler Holding.

Dockweiler expands its electropolishing capacities in Sweden, extending its range of products and services.

Dockweiler becomes the largest partner in the planning and construction of a factory in Thailand for tube components, primarily for the pharmaceutical industry.

Dockweiler launches its ASME-BPE program.

Dockweiler becomes a certified A-supplier for custom-made products made of tubes and tube components. Its highly developed orbital welding technology using special machines can produce the most difficult geometries.

Dockweiler develops "bubblers", complex transport and supply vessels made of stainless steel, used to transport organometallic compounds such as TBAs for the CVD process and can be directly coupled to the tool.

Dockweiler BV opens in the Netherlands.

Dockweiler recognizes the stricter requirements of the pharmaceutical industry and develops mechanically polished as well as electropolished tube systems for safe and economical plant engineering in pharmaceutics.

Dockweiler opens a subsidiary in Great Britain.

Dockweiler opens a subsidiary in Austria.

First major order to supply the material for the complete media supply of a greenfield chip factory in Holland.

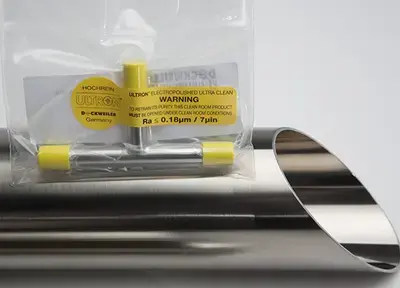

Dockweiler recognizes the need for better surfaces and higher purity and develops the "Ultron" product in collaboration with its electropolishing partner. Electropolished, topographically flattened, high purity. A milestone in the company history.

First major order for the new "Dockweiler TCC” product for a semiconductor factory.

Dockweiler becomes the representative for high-quality seamless stainless steel tubes and purifies them using special cleaning processes.

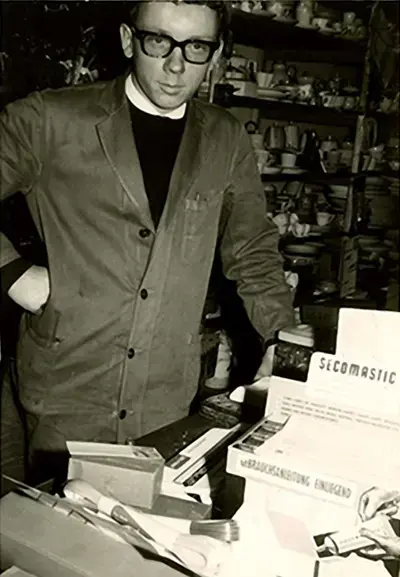

Klaus-Dieter Fiebig takes over from Bruno Dockweiler.

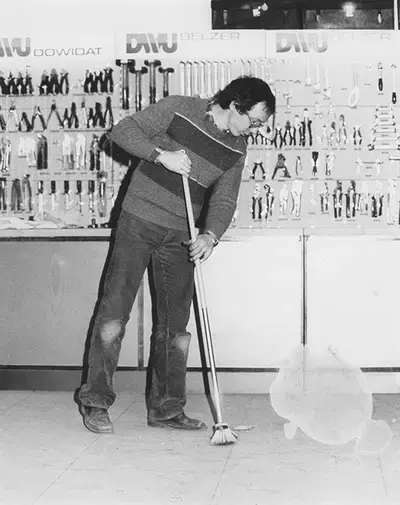

At the age of 16, Klaus-Dieter Fiebig starts his apprenticeship as a hardware dealer with Bruno Dockweiler.

Bruno Dockweiler founds a hardware store in Hamburg.