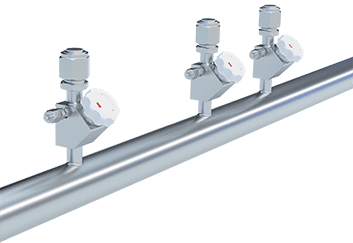

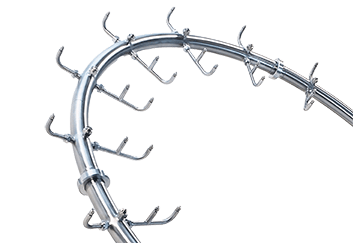

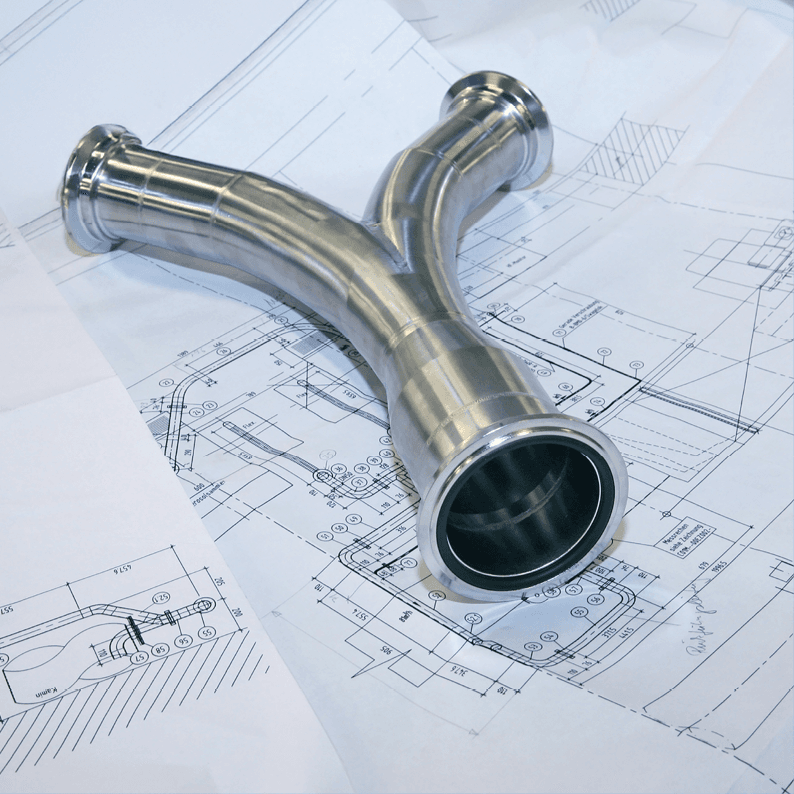

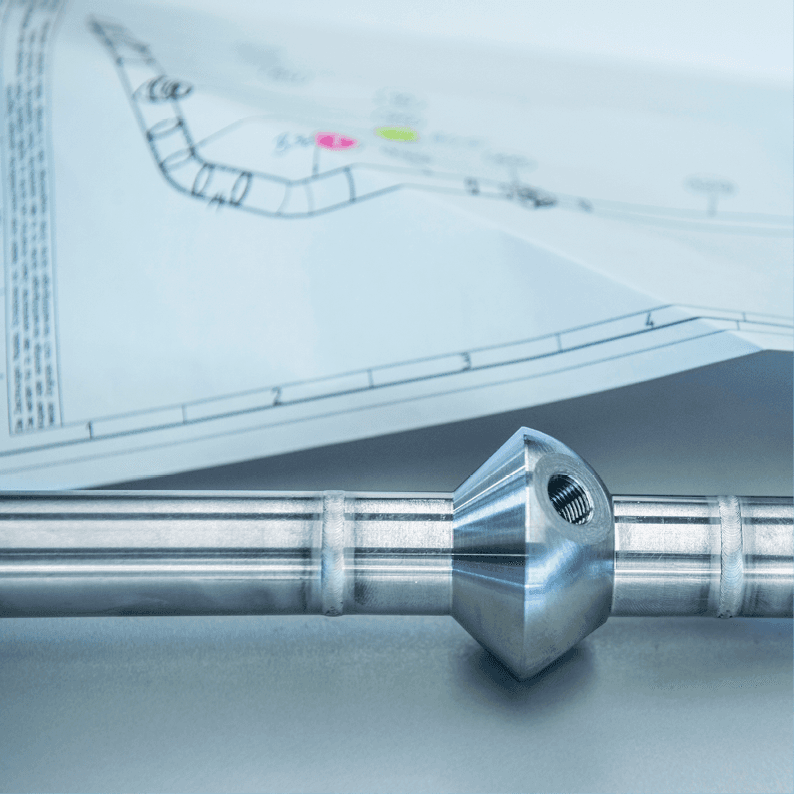

Years of experience in the development and production of stainless steel tube systems enable us to offer our customers customized solutions for process optimization. We work closely with our customers to develop specific solutions from rough sketches. When it comes to implementation, our motto is: “If you can draw it, we can make it.” Our experts translate your requirements into individual components and prototypes that are perfectly customized to your specific requirements and challenges.

We ensure the highest reproducibility by using TIG orbital welds. Targeted design optimizations enable IO welds, thus increasing efficiency in the manufacturing process. Innovative 3D bending processes reduce the number of welds and the risk of leakage, while at the same time minimizing the documentation effort. This is complemented by hygienic design with minimal dead space and smart space management for optimal use of even the smallest plant spaces.