As a technology partner to the semiconductor industry, Dockweiler supplies UHP tubes, molded parts and complex systems for gas and vacuum applications. Our goal: efficiency and safety through high-quality components tailored to the process - from consulting to clean room production.

Your specialist for microelectronics

High-purity solutions - perfectly customized to the requirements of the semiconductor and microelectronic component manufacturing industry. Whether it's the supply of semiconductor factories (fit-up or hook-up of FABs) or state-of-the-art lithography technology, Dockweiler has the right supply systems.

The perfect combination for high purity media

Maximum demands on quality

Dockweiler has been a pioneer in the semiconductor industry from the very beginning. Since the early 1980s, with the rise of the first personal computers, we have specialized in stainless steel tubes and fittings for this industry. Our components are prefabricated in certified production environments, manufactured under ISO class 4, 6 and 8 clean room conditions and have electropolished inner surfaces with roughnesses of up to Raavg. ≤ 0.25 µm, optionally even a maximum of 0.13 µm. Each item is 100% helium-tested for leaks - with leakage rates of 1 x 10-⁷ scc/sec for PCW and CFOS and 1 x 10-⁹ scc/sec for UHP products. Welding records, quality certificates and complete traceability via heat number and material class are a matter of course for us.

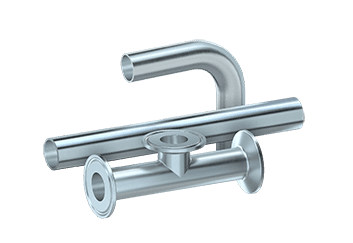

Microelectronics products

Dockweiler stainless steel tubes and fittings for the semiconductor industry are available to various standards (materials and internal surface finishes). The tube dimensions vary from an internal diameter of 3 millimetres (1/8") up to NPS 20.

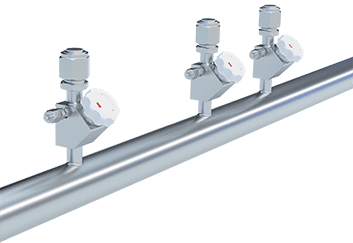

UHP Manifold Systems

Faster, safer, cleaner: Dockweiler's UHP distributors are individually manufactured, pre-assembled and delivered tested - for smooth installation and maximum process reliability. Less effort on site, more control in the factory - quality without compromise.

Find out more in our brochure - download now!

Perfect surfaces - because any contamination is one too many

Ready for the highest purity?

Our experts will be happy to support you - personally, competently and application-oriented. Get in touch now and find the right solution for your project.

Particle measurement and residual gas analysis (RGA)

At Dockweiler, the particle cleanliness of tube systems is determined in a clean room using two measuring methods: DPC (Discrete Particle Count) and CPC (Condensation Particle Count). The residual gas analysis determines the remaining content of water and volatile and non-volatile hydrocarbons after cleaning. Both methods document the cleanliness level defined by the customer before delivery.

We are absolutely strict when it comes to safety! Especially for highly reactive process gases, we quickly opt for the ultron tube.

Customer benefits

High Purity

Pioneer in the development of high-purity surfaces for the semiconductor industry

Industry standard

The Dockweiler surface finishes Finetron, TCC and Ultron are the industry standard.

Metallurgy expert

Specialists in metallurgy and optimization of stainless steel surfaces

More information

Flexibility without compromise

Maximum flexibility and the highest purity - with electropolished stainless steel corrugated hoses from Dockweiler Flextron, you can guarantee uncompromising quality for your processes. Ideal for applications in microelectronics and fine chemicals.

Manifolds tailored to your needs

Tailor-made manifold systems for maximum efficiency: our solutions offer the perfect distribution of media and adapt perfectly to your processes. Developed in ISO class 4 cleanrooms for maximum cleanliness and process reliability.

Precision in perfection

With over 30 years of experience in surface treatment, we guarantee the highest levels of purity and durability. Our processes such as electropolishing and pickling set new standards in the industry.